-40%

LEE Mold 6 Cavity Bullet Mold 90465 TL356-124-2R 9mm 38 Super 124 Grain 90465

$ 27.97

- Description

- Size Guide

Description

Lee Six Cavity Mold produces Six .356 diameter 124 grain tumble lube design round nose bullets for the 9mm Luger, 9x19mm Nato, 38 Auto, 38 Super Auto and other .355 cartridges.This is the best and fastest bullet design for the 9mm. Round nose for reliable feeding and tumble lube design for fast lubing with no sizing required. Simply coat the bullets with Lee Liquid Alox, and let them dry over night.

Lee aluminum molds are the best value in bullet molds.

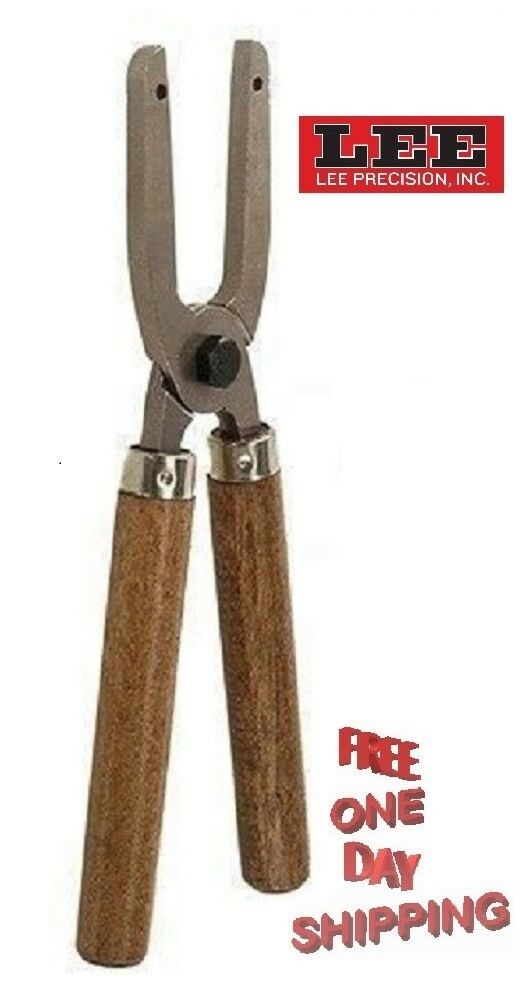

The blocks do not rust like cast iron molds, and are lightweight for less fatigue and ease of use. Handles are not included. the mold comes as pictured with the spruge cutter handle.

You can also quickly switch to a different mold while casting, as it can be quickly heated by dipping the corner of the mold in the lead pot. No other pre-warming required or wasting time with bad cast bullets while waiting for the mold to come up to temperature.

SUPER FAST CASTING WITH 6 BULLETS IN EACH POUR.

BRAND NEW IN FACTORY BOX, IN STOCK AND READY TO SHIP. WE ARE A LEE MASTER DISTRIBUTOR AND HAVE MANY OTHER GREAT LEE PRODUCTS LISTED.

Returns Accepted if you are not satisfied. We only list items that we have in stock and ship most orders by the next business day. Thanks for looking, check out our other items for great deals on shooting supplies and reloading equipment by clicking the following link:

Please visit our Ebay store, Shooting Supply

!

For Buyer protection, we can only accept payment thru PayPal, and can only ship to the address you provide at check out.

PLEASE BE SURE YOUR SHIPPING ADDRESS IS CORRECT WHEN YOU CHECK OUT. IT CANNOT BE CHANGED LATER.

Thanks for looking, Mark @ Shooting Supp

ly

From the Lee website:

Lee mold blocks are machined from aluminum blocks because of its exceptional molding qualities. Aluminum molds heat up and cool down faster than iron or steel molds so good bullets can usually be produced after only a few casts. Lee molds produce bullets faster than iron or steel molds due to the minimized down time between casts. In addition, they are one-third the weight of iron or steel mold blocks for less fatigue during extended casting sessions. To ensure the best possible bullets, mold block halves are clamped together and then lathe-bored for unmatched roundness and size control. All Lee 1- and 2-cavity molds come with mold handles and hard anodized sprue plates. Weights given are Lee's weights with suggested alloy; actual weight may vary due to alloy mixture used.